- Charlotte, NC USA

- polarjetnc@gmail.com

- (704) 953-8580

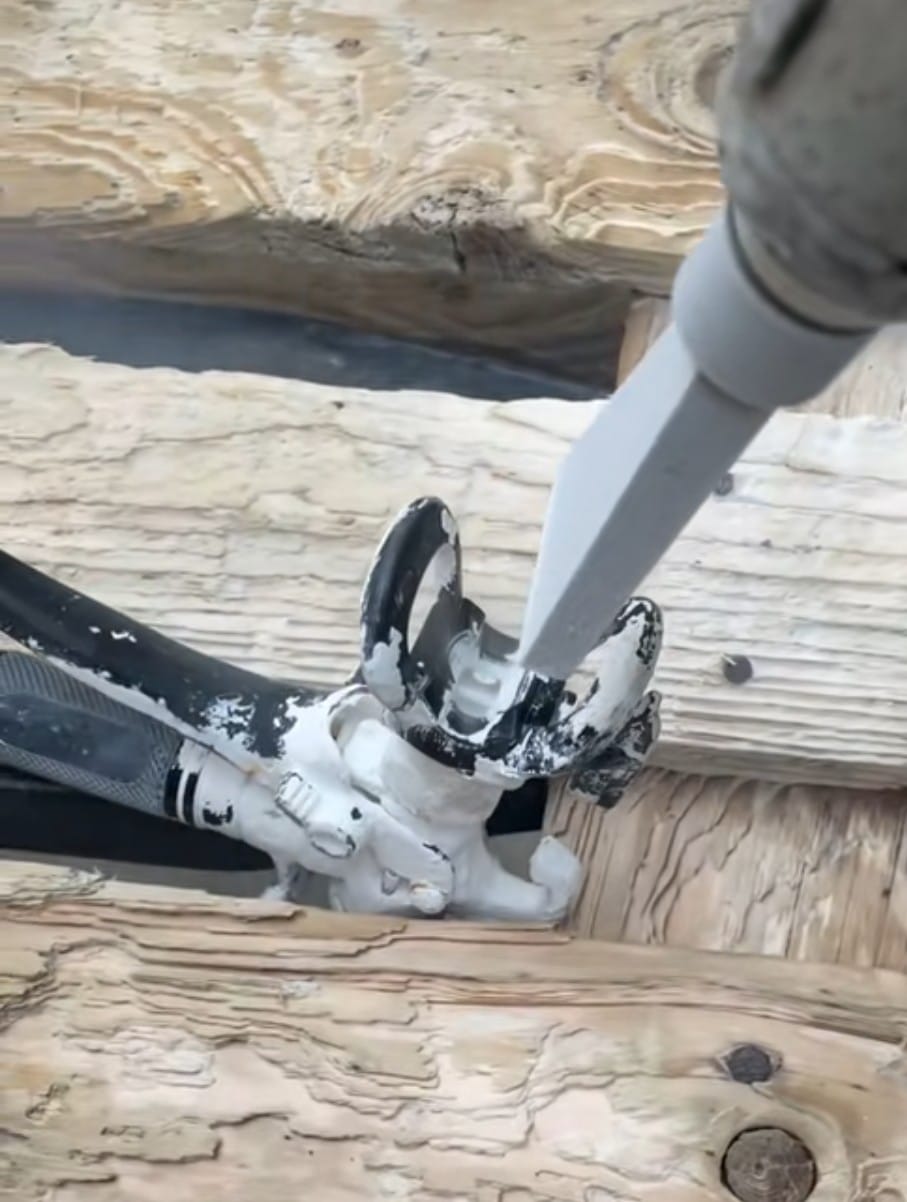

Commercial growth has reshaped much of Fort Mill, and with it comes the need for cleaning methods that won’t slow down production floors or disrupt busy facilities. Using dry ice blasting, we help manufacturing teams handle machinery equipment cleaning, and sensitive electrical cleaning without shutting everything down. It’s a practical fit for operations that depend on steady, dependable performance.

Restoration needs around town, whether from smoke issues, moisture problems, or aging infrastructure, also require a steady hand. Our approach supports local businesses through fire smoke remediation, mold remediation, and environmental abatement, all while keeping the process eco-friendly. The same gentle method helps with plastic and rubber mold cleaning, food production facility sanitation, and the careful upkeep needed for historical buildings.

We use controlled dry ice blasting for machinery, hard-to-reach components, and electrical equipment where traditional cleaning isn’t safe or efficient.

Fire smoke removal, mold remediation, and environmental abatement reduce hazards. It protects structures that have experienced damage or contamination.

Food production facility cleaning and transit system cleaning help maintain hygienic environments without water or chemical residue.

Our non-abrasive methods support the preservation of older materials and architectural details found throughout Fort Mill’s older neighborhoods.

WhatsApp us